AR400

This logo identifies all the machines made entirely or partially of AR400 wear-resistant steel (also called HARDOX 400). AR400 is not only very wear-resistant but also has excellent levels of solidity, which in many cases provide an advantage in terms of weight reduction.

S420

The symbol S420 indicates that the main components of the machine in question are made of special steel. This steel is particularly robust and resistant to deformation, which could also occur in the area of the weld seams. This high-strength steel is also often used in combination with wear-resistant inserts.

WEAR PLATE

All mulchers and tillers equipped with replaceable wear plates inside the chassis are marked with the WEARPLATE logo. The wear plates are always made of AR400 wear-resistant steel. Although the plates have a very long service life, they may need to be replaced after a certain period of time in the event of heavy-duty applications. This is quick and easy, and your machine will then be as good as new. DETAILS - CHASSIS - INTERIOR - CRUSHING

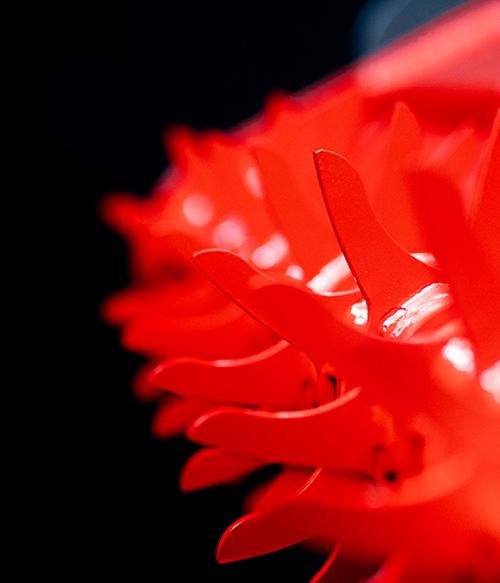

COUNTER CUTTERS

What some people don't know is that the actual shredding work in a mulcher is performed by the counter cutters. Depending on the model and use, a numerous series of counter blades is installed in the housing, and sometimes even under the hood, always with the aim of reducing dimensions and optimising the power demand. The SEPPI M. COUNTER CUTTERS are made of hot-forged steel and are shaped in such a way as to ensure excellent shredding performance on the one hand and a very long useful life on the other.

2CC

These devices are equipped with 2 complete rows of tempered counter cutters. On the S9 models, these counter blades are screwed on and are therefore easier to replace.

3CC

These devices are equipped with 3 complete rows of tempered counter cutters.

4 CC

These devices are equipped with 4 complete rows of tempered counter cutters.

5 CC

These devices are equipped with 5 complete rows of tempered counter cutters. A perfect shredding result! POWER TRANSMISSION

ADAM

The ADAM alignment system developed by Seppi M is used to optimally use the mulchers and tillers even on difficult terrain. By adjusting the angle of the transmission, the corresponding device is able to lift much higher and to drop much lower than normal. In all other situations, ADAM helps maintain an optimal drive shaft angle and thus protects the entire kinematic chain.

2SPEED

2SPEED identifies those machines equipped with a manual gearbox. The gearbox is used to manually change the speed directly on the tiller or mulcher, to work at a slow or fast speed. The drive shaft always runs at the optimum speed, which is 1000 rpm.

2SPEED POWERSHIFT

2SPEED POWERSHIFT identifies machines equipped with an electro-hydraulic gearbox. The difference compared to the simple 2SPEED is the fact that the gearbox changes the rotation speed of the tiller directly from the ISOBUS terminal of the tractor while the machine is running. This means being able to quickly and conveniently switch from slow to fast gear and the machine can be flexibly adapted to the working conditions at any time. The drive shaft always remains at the optimum speed, i.e. 1000 rpm.

GEAR DRIVE

In these machines, the power is not transmitted to the rotor through the usual pulleys and V-belts but through a series of gears. Compact installation space, high transmissible torques and continuous lubrication are just some of the many advantages of this technology.

CARBONCHAIN

Power is transmitted via special carbon fibre belts. Due to the extreme tensile strength of this material, its transmission is comparable to that of a steel chain. The carbon belt also boasts the added advantage of having almost no friction loss and requiring no lubrication. Through the latter it is possible to transmit high torques and powers of up to 500 HP.

HYDRAULIC DRIVE - MOTORS

VARIO FLOW

VARIO FLOW identifies engines with adjustable displacement. Thanks to the Vario-Flow technology, the engine displacement is always adapted to the available flow rate. In this way the best working result is obtained for a hydraulic mulcher. Its flexibility is a constant feature with the ability to also use the machine on other vehicles.

PISTON MOTOR

This logo designates our hydraulically-operated products, equipped with a highly efficient piston motor. Our accessories, recognisable with this logo, work with maximum performance and high efficiency. They are therefore suitable for the most demanding applications.

M-BOOST

The M-BOOST logo is found on machines with hydraulic transmission equipped with piston motors and automatic displacement adjustment. The M-BOOST technology has all the advantages of piston motors and also has the benefit of automatically varying the torque depending on the load. This results in even more efficient work, both on large and small transport vehicles. The M-BOOST motor is always adaptable!

PLUG & PLAY

With the PLUG & PLAY hydraulic motors, the mulcher can be easily connected to the excavator without having to first measure and adjust the flow rate to the excavator. Preparing the machine for work has never been easier. ROTORS AND TOOLS

HELIX

Most SEPPI M. mulchers have this feature right from the start. The logo identifies machines with tools or hammers arranged in a spiral on the rotor shaft. This results in incredibly smooth operation, as well as low energy requirements and reduced noise generation and, last but not least, an excellent work result.

CARBIDE

The CARBIDE logo identifies tools with tungsten carbide inserts, a very resistant hard metal for a maximum durability. As a rule, all the fixed tools have CARBIDE inserts. With this material, a service life of up to 5 times longer than traditional hammers can be achieved. A classic is the MINI DUO tool; all V-LOCK tools are also supplied in this material.

V-LOCK

Intelligent and efficient! This innovative tool system impresses with its perfect fit which makes it unique: it gives an outstanding stable hold and allows an easy replacement in a time and effort saving manner Watch this video for more details: https://www.youtube.com/watch?v=y3C_FIzPDU0

CUT CONTROL

Everything’s under control with MINI BLADE cutting tools and the special designed cutting depth limiter. Much like the raker on a chainsaw, the limiter controls the depth of cut and helps to prevent rotor stall which ensures an easy and high-quality mulching operation.

RIC

The acronym RIC stands for "Radial Interference Cut". It is a patented system that obtains fine and even shredding without the need for sieving plates. The secret is that the material is radially pressed against the counter blades, where it is crushed by the overlapping tips of the tools. The use is especially important for pick-up mulchers, i.e. for tasks that require a particularly fine chopping result.

FREE ROTOR

Seppi M. calls the rotor with free oscillating tools FREE ROTOR. With this type of rotor, the hammers are installed in such a way that they can move freely 360° around their axis, thus avoiding kickbacks. This technology has been used for a long time, especially in forestry mulchers, and excels at very fine and clean shredding of wood measuring up to 30 cm in diameter. ATTACHMENT OF THE EXCAVATOR

FLOAT

The FLOAT floating device allows the mulcher to oscillate so that it can freely follow the contour of the ground. With just one bolt, the floating device can be locked at any time if conditions so require. ATTACHMENT

PENTALINK

With the PENTALINK system, tools that generate very high side loads, such as the SBM, SBM tele and L9 flex, can be attached to the tractor. To ensure stable and safe working, the tools are connected to the tractor at five points with the PENTALINK system: 3 points as usual and 2 additional points on the tractor axle. The lift retains 100% of its functionality for any other attachment.

FR

The FR logo indicates the reversible mulchers, that is, tools can be attached to them at the front or rear. A wide variety of combinations are available: Pushed front, pulled back or pushed back, i.e. retroverted. More details can be found in our technical documentation.

FLEX-SAFE

FLEX-SAFE is a system that protects the mulchers from damage caused by collisions with obstacles such as stones or roots. For example, it allows the SMO avs or L9 flex side mulchers to flexibly absorb shocks and thus avoid overloading both on the mulcher itself and on the tractor. This makes working at high speed possible without compromising safety.

SPACE LINK

The mobile tension mast, called SPACELINK by Seppi M., supports the weight of the machines on the mounting frame and moves them gently over rough terrain. In combination with the FLEX-SAFE collision protection, the unit is lifted over obstacles by the SPACELINK mast.

P-SHIFT

A parallelogram lateral displacement has the advantage of allowing a large displacement in the required situations. This allows reaching of the most difficult points, for example under the canopy of trees, in ditches or on slopes. Greater reach is the key to easier and safer work.

DIFFERENT DETAILS / PROPERTIES

4D ROLLER

All four direction bearings installed on the support roller, capable of withstanding the weight of our equipment and absorb the side load during turns or while working sideways on slopes. Extended roller-bearing life, for heavy duty applications.

BOLTED SHAFT

Replaceable stub shaft on the rotor axle. Thanks to the particular way of manufacturing, the shaft becomes very reliable against impacts and stress. In the very unlikely event of damage, the shaft only is an easy replacement part.

M-FLAP

This is the adjustable rear hood of a hammer mulcher. With the variable and continuously adjustable mulching deflector, the opening can always be adjusted to obtain optimal work according to the material to be shredded while at the same time minimising power absorption

DUAL

The DUAL logo on the BMS-L model indicates that the machine is built symmetrically and has two hoods, both of which can be opened. This allows the user to flexibly adapt their machine to the working conditions.

LOW PROFILE

The LOW PROFILE logo refers to those machines whose construction has been designed to be as low as possible. With the MINI-BMS and BMS-F models, it is possible to position a tilting fifth wheel and a support interface while maintaining an overall height reduced to a minimum. With MINIFORST cl, however, this feature is important for the driver to have a good view of the work area.

SANDWICH SKIDS

With the so-called skids, the sidewalls are inserted into a frame with a sandwich structure and thus reinforced. When the weight of the excavator is supported on the mulcher, the forces are transferred to the mulcher housing.

BIONIC FEED

Collecting material is one of the most difficult tasks for pick-up mulchers. Seppi M.'s technical solution uses nature as its model. The pick-up device replicates the shape of human fingers and thus ensures a perfect grip on the cut timber and branches.

SOFT TOUCH

Highly sensitive hydraulic toucher, that senses the plants along a row in orchards or vineyards. This guides the implement along to ensure the cleanest possible job, without damaging or stressing the plants.

ISOBUS

SEPPI now applies an ISOBUS control system as standard on many of these machines! On ISOBUS-compatible tractors, the ISOBUS socket of the mulcher is connected to the tractor and some functions are controlled or monitored directly on the on-board computer in the tractor or excavator cab.

M-CONNECT

Connect your mulcher to the internet with M-CONNECT by SEPPI M. Thanks to M-CONNECT, many operating parameters are recorded and saved for subsequent evaluation in both operational and agronomic terms. And with convincing results too: accurate operating data for improved cost calculation, information on the servicing status of machines, and an objective recording of the activities for both the owner of the land and the contractor.

AUTO TRACK TENSION

Self-tensioning track. The individual track are tensioned by a hydraulic system, which regulates the tension according to the conditions of the ground and prevents the track from striping or breaking.

HIGH GRIP

The high traction tracks have a high profile to ensure excellent stability and grip on slopes up to 55° in optimal conditions.

M-TURBO

The hydrodynamic couplings are adjustable to adapt optimally to the tractor power. When the PTO speed drops below a defined value (e.g. 1300 engine rpm) under heavy load on the drive, the rotor of the mulcher is decoupled and prevents the tractor engine from stalling. The rotor can come to almost a complete standstill in this case but must be lifted immediately so that the clutch engages again. Since the engine speed does not drop too far, all hydraulic functions of the tractor always remain 100% functional and reactive. Mainly recommended when mulching stumps that put extra stress on the tractor.